Plastic Conveyor Roller Sleeves Streamline Material Transport for Manufacturers

As consumerism and commercialism have grown globally over the years, the need to find high-quality products that provide adequate production has been a major focus for manufacturers of all kinds. Plastic conveyor roller sleeves have offered an amazing solution to this challenge. Inplex’s plastic conveyor roller sleeves help streamline material transport for manufacturers around the country.

Conveyor roller covers have many benefits for manufacturing businesses that need to transport materials and products. In fact, the conveyor rollers market is set to reach approximately $1.939 billion by 2026, which could increase the demand for roller covers that help businesses run more efficiently.

However, plastic rollers for conveyors come in a variety of materials, each of which has its own advantages. For example, urethane roller sleeves may work better than ultra-high molecular weight polyethylene (UHMW) for a specific business and vice versa. Keep reading to learn about the benefits of plastic conveyor rollers and some of the most common roller cover materials.

What Are Conveyor Roller Sleeves?

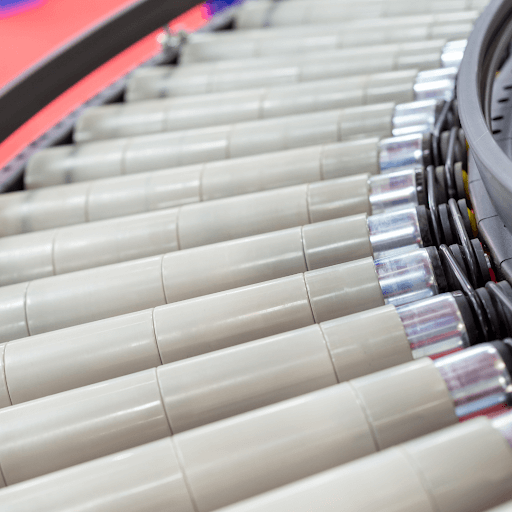

Rollers, or conveyor roller sleeves, are a part of a conveyor system that allows the movement of an item in an assembly or processing line. Plastic is used to cover the rollers on conveyor belts that transport materials or products during manufacturing. They can slide onto the conveyor rollers using lubricant and an air nozzle, or you can find a material that will shrink to the size of the rollers when you apply heat.

How Do Conveyor Roller Sleeves Help With Material Transport?

Part of manufacturing is the potential that some of your products will ultimately end up becoming damaged goods.

Successful businesses calculate the cost of these lost goods and strategize how to limit it as much as possible. Plastic conveyor roller sleeves offer a great way to decrease the chance of poor-quality materials.

Plastic conveyor roller sleeves provide the following advantages:

- Reduce scratches and marks on the materials and the conveyor system

- Provide extra padding for products as they move along the conveyor

- Provide traction for products to move more safely

- Reduce noise and vibrations while the conveyor is running

Because of frequent use, the high volume of moving product over time naturally creates wear and tear. Plastic conveyor roller sleeves not only help during material transport to protect your goods and products but also safeguard the foundational parts of your conveyor belt system, allowing them to depreciate slower over time.

What Are The Benefits of Using Plastic Rollers for Conveyors?

While there are several types of conveyor systems that can each be made out of many different materials, systems that use plastic conveyor roller sleeves offer unique benefits that all manufacturing warehouse and supply chain managers should be aware of.

While there are several types of conveyor systems that can each be made out of many different materials, systems that use plastic conveyor roller sleeves offer unique benefits that all manufacturing warehouse and supply chain managers should be aware of.

1. Durability

Decreasing costs is part of increasing profitability. Some rollers crack under the pressure of heavier items, or the speed at which production has to move.

But when you choose a plastic roller conveyor, especially one crafted by Inplex, you are choosing a lightweight product with high longevity that can withstand a number of different masses as well as moisture. This allows each item to safely be moved as quickly as possible, helping you to reach your production goals with ease.

2. Plastic Is Economical

It’s true that metal roller conveyors are a common industry choice for manufacturers. These other products are typically created in an aluminum or stainless steel alloy.

While steel or metal rollers have their benefits, these metals are difficult to procure. Plastic conveyor roller sleeves offer a much cheaper alternative for industrial companies.

3. Easy to Repair or Replace If Needed

By plastic conveyor roller sleeves being cheaper to install, it also means that should you need a replacement roller, you can get one quickly, it doesn’t shut down the entire line of rollers, and it can also be purchased at a cheaper price.

Some manufacturing conveyor systems use a motorized belt to transport goods. Running a system with these motorized belts can cause major issues though since they are electrically powered. If unable to get proper power to run, it inhibits the entire chain of movement, while also being difficult and costly to diagnose the exact problem.

With a plastic roller conveyor, you also don’t have to waste time and money on routine maintenance. An added benefit of plastic conveyor roller sleeves is that they do not require lubrication, whereas metal rollers need this on a regular basis to avoid reducing their production capabilities.

4. Maintain Factory Cleanliness Standards

Covid changed the outlook and daily operation of manufacturing forever. With products being sourced and shipped from all over the world, contamination is inevitable.

Manufacturers can easily remain up-to-code on factory cleaning standards as well as remain proactive in disinfecting with plastic conveyor roller sleeves. Plastic is easily cleaned, while liquid cleaning materials can corrode metal conveyor rollers over time, causing rust and rough surfaces that can damage products or prevent smooth transitions.

5. Utilized In A Number of Industries

Due to being an economical solution with many other great benefits, plastic conveyor rollers are the perfect solution. Utilized in a number of industries for procurement, supply chain, and manufacturing, they quickly and safely move goods as needed.

Plastic roller conveyors are suitable for manufacturing in the medical, CPG, oil & gas, highway industries, and more! View the full list of industries Inplex helps to see how they offer their services to a wide range of manufacturers.

6. Fully Customizable

Factory layouts and conveyor types often mean custom plastic rollers for conveyors are needed. With Inplex’s professional and full-service capabilities, we can easily fit to your extrusion needs when you choose plastic for your conveyor roller sleeves – however custom they may be!

Factory layouts and conveyor types often mean custom plastic rollers for conveyors are needed. With Inplex’s professional and full-service capabilities, we can easily fit to your extrusion needs when you choose plastic for your conveyor roller sleeves – however custom they may be!

With plastic extrusion, custom shape profiles are able to be provided. At Inplex, our customization goes further. We offer a variety of custom colors to keep your options open and provide the best service we can to our customers.

Don’t see your industry? Reach out to us anyways and we’ll help you find a custom solution!

Inplex Offers High-Quality Materials for Plastic Conveyor Rollers

As mentioned above, conveyor roller sleeves can come in many different types of materials. Even plastic rollers have numerous options, each with its own set of additional benefits. Take a look at some of the most common types of plastic Inplex uses to produce high-quality plastic rollers for conveyors.

As mentioned above, conveyor roller sleeves can come in many different types of materials. Even plastic rollers have numerous options, each with its own set of additional benefits. Take a look at some of the most common types of plastic Inplex uses to produce high-quality plastic rollers for conveyors.

Polyurethane Roller Sleeve Options

Polyurethane roller sleeves provide a softer, more flexible material that can be applied with an air tool to help it slide onto the conveyor roller. Polyurethane and urethane roller covers can also adhere to the conveyor rollers to fit the exact dimensions. They are especially helpful for creating traction on steep inclines.

The applications of polyurethane vary greatly due to its durability. It can withstand regular wear and tear, and resist abrasions caused by manufacturing activities. In addition, urethane conveyor rollers can tolerate a wide range of temperatures.

Vinyl Plastic Rollers for Conveyors

Vinyl, also known as polyvinyl chloride (PVC), is another material choice that can be fitted to the size of conveyor rollers. It is a strong material that can resist abrasions while transporting materials.

It is advantageous because of its resistance to chemicals, which makes it easy to clean and can prevent corrosion on the conveyor system. Inplex makes sure to offer vinyl product material in both rigid and flexible options.

Interested in vinyl but not sure which type to choose? To gain a deeper insight as to whether rigid or flexible would be the best choice, check out our blog on rigid versus flexible vinyl!

UHMW Polyethylene Conveyor Roller Sleeves

Ultra-high molecular weight (UHMW) polyethylene is a more rigid material that provides a looser fit on conveyor rollers. While it is also a very durable material, it is perhaps most well-known for its ability to reduce friction.

In terms of conveyor belts, it helps keep products moving even once the conveyor stops, which helps reduce energy costs. In addition, it doesn’t absorb a lot of moisture, and it can resist damage from most chemical cleaners.

But Inplex’s list of materials doesn’t end there. Check out our full list of offered materials to see which would be the best for your custom plastic extrusion project!

Explore Plastic Conveyor Roller Sleeves And More From Inplex

While every material has its benefits, it’s clear to see how choosing plastic for your conveyor roller sleeves remains a top choice for manufacturers across numerous industries.

By offering a variety of materials, including polyurethane, rigid and flexible vinyl, and UMHW polyethylene, Inplex ensures that your custom extrusion needs will be satisfied. We provide these materials in a wide range of shapes and sizes, as well as custom colors to match your business’s branding.

So let’s get rolling on your manufacturing solution! Contact Inplex today to get a quote for your custom order of conveyor roller covers.

Back to Blog