Polycarbonate

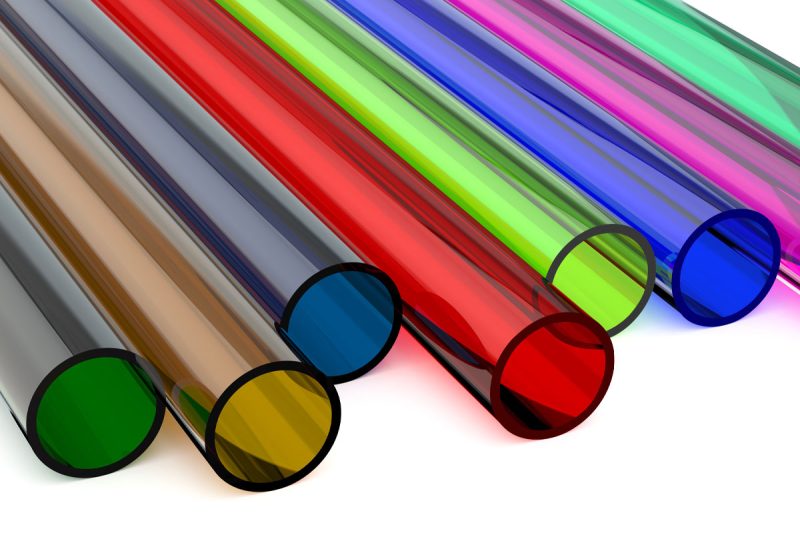

A versatile and optically transparent thermoplastic that provides an array of useful features.

What is Polycarbonate?

Polycarbonate is a thermoplastic that is well-suited for extrusion into tubes & profiles.

Polycarbonate material is quite pliable and can withstand angle bends and plastic deformations at room temperature, it is well-suited for extrusion into tubes, rods, and profiles.

Polycarbonate is well known for its toughness, temperature resistance, impact resistance, and workability in molding and thermoforming. As a thermoplastic, polycarbonate material does not get burned when subjected to extreme temperatures. Instead, polycarbonate gradually transitions from a solid to a liquid at its melting point of 155 degrees Celsius. This gradual melting means that polycarbonate can be shaped by continually cooling and reheating the material. As a result, polycarbonate is the most common material to undergo manufacturing processes involving injection molding.

Polycarbonate is a good electrical insulator and can be used in a wide variety of applications. In addition to its extrusion applications, polycarbonate is also widely used as the primary material in manufacturing electronic components and media discs such as CDs and DVDs. Injection-molded polycarbonate can also be found in automotive, aircraft, and railway components.

The most notable drawback of polycarbonate material is that it is susceptible to scratching. Polycarbonate is UV stable and available in FDA grades.

Although polycarbonate is usually clear, we can also accommodate custom orders so that you can use the color of your choice.

Have any questions about our usage of polycarbonate in plastic extrusion? Get in touch today!