Rigid Vinyl (RPVC)

As the name suggests, Rigid Polyvinyl Chloride (RPVC) boasts superior rigidity.

What is Rigid Vinyl (RPVC)?

Priced moderately and manufactured by using raw materials like rock salt and natural gas, rigid vinyl offers excellent resistance to weathering and water, although RPVC should be heat-stabilized to deal with high temperatures.

The material can also be UV stabilized through the use of additives, which offer increased resistance to sunlight. By definition, rigid vinyl has not been modified through the use of plasticizers, which are sometimes applied to make the vinyl softer and more flexible.

Rigid vinyl is susceptible to strong solvents, including esters and hydrocarbons. Furthermore, unless it is ordered according to FDA-approved grades, tubing made from rigid vinyl is not safe for drinking water. This is because PVC can contain chemical additives like lead, cadmium, and phthalates.

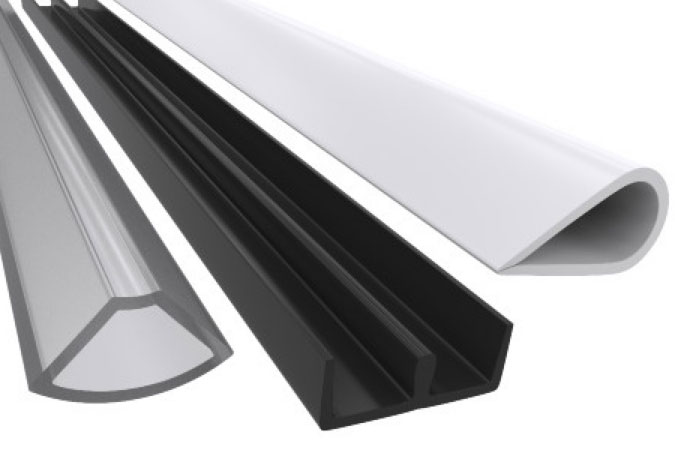

RPVC’s water resistance makes it suitable for use in windows, doorways, wire coverings, and wastewater pipes. Rigid vinyl can also be used to create plastic film that can be made matte, opaque, or glossy.

Rigid vinyl’s combination of rigidity, all-around utility, and affordability makes it a good choice for plastic tubes or profiles. It is available in clear or colored varieties and can be ordered in either FDA or outdoor grades.

Have any questions about our usage of rigid vinyl in plastic extrusion? Let us know!