What Is Rigid Vinyl and Why Should I Use It?

Rigid vinyl is a sturdy vinyl type that offers excellent properties for plastic extrusion projects. As a result, many industries use rigid vinyl in plastic profiles, tubing, and other products.

While Inplex offers many plastic materials for our clientele’s custom plastic extrusion, rigid vinyl is an excellent choice for many of our customers. While your plastic extrusion material choice depends on your plastic extrusion project needs, rigid vinyl has a lot to offer and we are proud to provide it in our wide selection of plastic extrusion materials.

Inplex Custom Extruders is a plastic extrusion manufacturer that can help you produce custom-extruded rigid vinyl for numerous projects and applications. Read on to learn more about rigid vinyl, how it differs from Inplex’s flexible vinyl, and how its benefits can help you!

What Is Vinyl? Why Is It Popular in Plastic Extrusion?

While a common enough term, many people have not taken the time to truly understand this useful plastic extrusion material. Vinyl is used in everything. From custom plastic extrusions to flooring, and more, it’s commonly used throughout our daily lives. Before we dive into what rigid vinyl is, let’s establish a clear understanding of the base plastic material, vinyl.

While a common enough term, many people have not taken the time to truly understand this useful plastic extrusion material. Vinyl is used in everything. From custom plastic extrusions to flooring, and more, it’s commonly used throughout our daily lives. Before we dive into what rigid vinyl is, let’s establish a clear understanding of the base plastic material, vinyl.

Also known as PVC or polyvinyl chloride, vinyl is a flexible, fire-resistant, and waterproof plastic polymer that can be used in a wide range of products and industries. The PVC production process consists of the following steps:

- Extracting hydrocarbon resources and salt

- Producing chlorine and ethylene from hydrocarbon resources and salt

- Combining ethylene and chlorine to make the vinyl chloride monomer (VCM)

- Polymerizing VCM to create PVC

- Mixing PVC with other materials to create different formulations with various physical properties

Ready to learn more about the other plastic extrusion product, services, and materials that Inplex provides? Visit our blog, where we happily provide a free educational resource to intrigued clients.

What Is Rigid Vinyl? Why is Rigid Vinyl Used in Plastic Extrusion?

Now that we have a base understanding of vinyl, let’s expand your knowledge further with rigid vinyl. Vinyl comes in two basic forms: rigid and flexible.

Rigid vinyl is a sturdy type of vinyl. Also known as rigid polyvinyl chloride (RPVC), rigid vinyl provides excellent resistance to water and chemicals. RVPC is mostly used in construction and plumbing but read on to see its full industry potential.

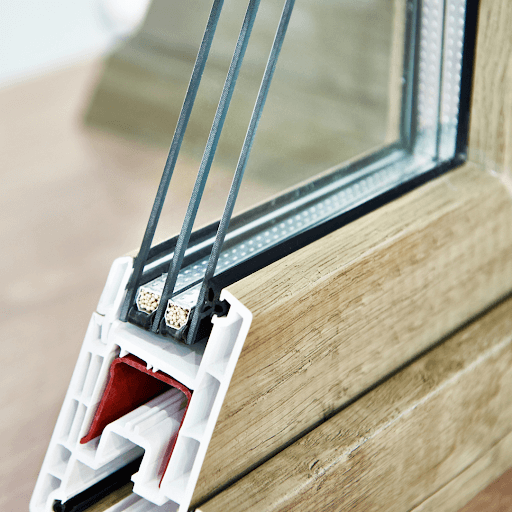

Thanks to its water resistance, rigid vinyl is best used for wastewater pipes, doorways, windows, and wire coverings. Manufacturers can also use rigid vinyl to create glossy, opaque, and matte plastic films for protecting personal care products, medicines, and household goods. Inplex offers rigid vinyl in both colored and clear varieties to provide a custom extrusion experience. This is just one of the many custom services we provide when catering to your extrusion needs.

The sturdiness and water resistance of rigid vinyl make it very popular in custom plastic extrusion projects for various industries that need durable material. It is economical and reliable, making this resource an ideal plastic extrusion option!

Main Differences Between Rigid Vinyl and Flexible Vinyl

That’s right, there’s another vinyl option as well! Inplex offers both rigid and flexible vinyl to remain adaptable to whatever our customer needs.

But which would be right for your project? Well, while both are types of vinyl, they each offer unique differences you should pay attention to when making your selection.

Flexible vinyl — also known as flexible polyvinyl chloride or FPVC — is a versatile type of vinyl. Manufacturers usually create flexible vinyl by adding plasticizer or another additive to its rigid variant. FPVC is usually used in plastic packaging and can be modified into unconventional shapes, such as jar lids.

The main difference between rigid and flexible vinyl is that rigid vinyl has not been modified by plasticizers. As a result, it boasts superior rigidity, making it a popular choice in profiles and tubing. It is also highly water-resistant.

Many companies use flexible vinyl for plastic packaging, but it can also be used in home construction, especially in wall coverings, roofing, and flooring. Flexible vinyl can take shape in a broad range of forms, including various liquids, chemicals, and gases.

If flexible vinyl seems to fit your custom extrusion project, check out our detailed guide on flexible vinyl’s uses, benefits, and more.

The Top Benefits of Rigid Vinyl Plastic Extrusion

While flexible vinyl has a lot to offer, rigid vinyl has just as much! There are several reasons why organizations should use rigid vinyl.

While flexible vinyl has a lot to offer, rigid vinyl has just as much! There are several reasons why organizations should use rigid vinyl.

1. Is Rigid Vinyl Weather and Water Resistant?

Yes! Rigid vinyl provides excellent water and weather resistance. Over time, and with repeated use or exposure, plastic parts can be worn down causing issues when breaking. Organizations can avoid this by choosing rigid vinyl as their material. With the ability to heat-stabilize at high temperatures and eliminate mold and mildew, rigid vinyl is a sturdy material that can keep water and the elements out.

2. Does Rigid Vinyl Have a High Capacity for Tolerating Pressure?

Yes again! While different types of plastic are easily cracked or broken, rigid vinyl is different. Unlike flexible PVC, rigid PVC can tolerate an extreme amount of pressure. With increased durability, rigid vinyl allows you to achieve longevity and increase quality. It is also less prone to kinking at lower densities.

3. Is Rigid Vinyl an Affordable Plastic Extrusion Material?

Very much so! Rigid vinyl offers an affordable alternative to expensive materials like metal. By decreasing the costs put into your custom rigid polyvinyl chloride applications, you can reap the benefits while increasing your overall profit margin.

4. What Is Its All-Around Utility?

There are many custom rigid polyvinyl chloride applications, including plumbing pipes, plastic film, and uses in wire coverings, windows, wastewater pipes, and doorways. If you order it according to FDA-approved grades, you can use rigid vinyl tubing for applications for drinking water or food.

With four core benefits like this, rigid vinyl is a top contender at Inplex for extrusion plastic material. Due to how these four advantages are broad goals many companies look for in a product, rigid vinyl is utilized in a number of industries.

Industry Applications for Rigid Vinyl

With such great benefits, it is easy to see why rigid vinyl is a key choice for extrusion materials across many industries. If you’re still not sure if rigid vinyl would be appropriate for your company, seeing how others use it can be helpful. The top industries and products that use rigid vinyl regularly include:

- Construction: plumbing, flooring, window components, doorway components

- Automotive: dashboards, body parts, interior molds

- Electrical: tape, pipe insulation, electrical wire conduit

- Industrial Packaging/Manufacturing: films, bottles, pipes, wires, fittings, sheets, profiles, cables, tubing, conveyor rollers

With a number of excellent uses and potential benefits, custom rigid polyvinyl chloride applications can provide a great advantage to your custom plastic extrusion project or product.

The Inplex Difference – Manufacturing Rigid Vinyl for Your Custom Plastic Extrusions

Finding the right plastic extrusion company for rigid vinyl products can be challenging, especially if you have never done it before. But when your quality standard starts with your plastic extrusion supplier, you can trust your product will do its job.

Fortunately, Inplex Custom Extruders is here to help. Our team of plastics engineers and experts has over 50 years of experience in manufacturing rigid vinyl. We are also experts in designing customized products for a variety of markets, including industrial, construction, oil and gas, electrical, lighting, and outdoor living.

Interested in learning more about how we can help you? Request a quote for your next custom rigid vinyl plastic extrusion order or contact Inplex today.

Back to Blog