The Benefits of Using Custom Plastic Profiles in Construction & Architecture

Custom plastic profiles offer numerous benefits for the construction and architecture industries, from their versatility in design to their durability, cost-effectiveness, and energy efficiency. These profiles provide architects and builders with the flexibility to create innovative and aesthetically pleasing designs, while also offering long-term performance and sustainability.

As the demand for sustainable, cost-efficient, and durable materials grows, custom plastic profiles will continue to play a crucial role in shaping the future of modern construction and architecture. Let’s take a closer look at the benefits.

Versatility in Design

One of the most significant advantages of using custom plastic profiles in construction is their versatility in design. Architects and builders can work with a variety of plastic materials, such as PVC, polyethylene, and polypropylene, each offering different characteristics suited to specific needs.

Custom plastic profiles can be tailored to fit any design, whether it’s for windows, doors, facades, or even structural elements like roofing and flooring systems. The ability to create profiles in various shapes, sizes, and colors allows designers to integrate plastic components seamlessly into a building’s overall aesthetic, enabling more creative and flexible design solutions.

Durability and Longevity

Custom plastic profiles are renowned for their durability and resistance to environmental factors such as moisture, temperature fluctuations, and UV exposure. Unlike wood or metal, plastic profiles do not corrode or degrade over time, even when exposed to harsh weather conditions. This makes them particularly suitable for use in outdoor construction applications, such as window and door frames, cladding, and exterior facades.

For instance, plastic profiles made from UV-resistant materials can withstand prolonged exposure to sunlight without fading or becoming brittle. This makes them an ideal choice for areas that experience high levels of sun exposure.

In addition, plastic profiles are highly resistant to moisture, preventing issues like rot, rust, or mold growth, which are common problems with other materials like wood and metal. As a result, buildings featuring custom plastic profiles tend to require less maintenance and have a longer lifespan, reducing both repair and replacement costs over time.

Lightweight and Easy to Install

Another significant benefit of custom plastic profiles is their lightweight nature. Compared to traditional materials like metal or concrete, plastic profiles are much lighter, which makes them easier to handle, transport, and install. This reduction in weight can lead to lower labor and transportation costs during construction, as workers can handle the materials more easily and require less specialized equipment for installation.

The ease of installation is particularly advantageous in applications such as window and door framing, where precision and speed are essential. The lightweight yet strong nature of plastic profiles also allows for quicker installation times, contributing to faster project completion and lower overall labor costs.

Cost-Effectiveness

Custom plastic profiles offer a cost-effective alternative to traditional building materials. The manufacturing process for plastic profiles is relatively inexpensive, and because plastic is abundant and widely available, it helps keep material costs down.

Additionally, plastic profiles often require less maintenance than wood or metal, which can be prone to wear and tear over time. These long-term cost savings, combined with the initial lower material costs, make custom plastic profiles a budget-friendly choice for construction projects.

Moreover, custom plastic profiles can be made to order, meaning manufacturers can create the exact specifications needed for a project, reducing material waste and optimizing the use of resources. This efficiency in production further contributes to the overall cost-effectiveness of using custom plastic profiles in construction.

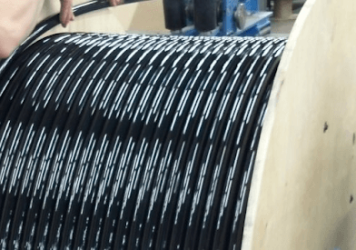

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US, with over 50 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog