The Impact of Precision Tooling on Plastic Extrusion Efficiency

Plastic extrusion is a cornerstone process in modern manufacturing, shaping everything from packaging materials to automotive parts. At the heart of this process lies the critical role of tooling, specifically precision tooling, which can dramatically influence the efficiency, quality, and overall success of extrusion operations.

For companies seeking to optimize their plastic extrusion workflows, understanding the impact of precision tooling is essential. Let’s take a closer look.

What is Precision Tooling in Plastic Extrusion?

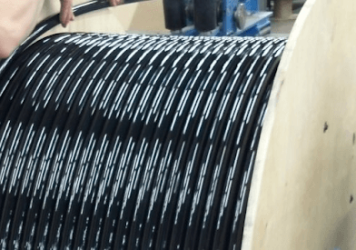

Precision tooling refers to the design and manufacturing of molds, dies, and related components with exacting tolerances and high-quality materials. In plastic extrusion, the tooling guides molten plastic through a die to form continuous profiles or shapes. The accuracy and durability of these tools directly affect the dimensional consistency, surface finish, and throughput of extruded products.

Enhanced Dimensional Accuracy and Consistency

One of the most significant impacts of precision tooling is improved dimensional accuracy. When tools are engineered to exact specifications, the plastic melt flows evenly and predictably through the die. This ensures that the extruded profiles maintain consistent thickness and shape, minimizing variability from batch to batch.

For manufacturers, this consistency reduces scrap rates and rework, saving both time and material costs. It also ensures that final products meet stringent industry standards and customer requirements, building trust and reliability in the supply chain.

Increased Production Speeds and Throughput

Precision tooling not only improves quality but also enhances production efficiency. High-quality tools minimize flow disruptions and pressure fluctuations within the extrusion process. This smoother operation allows manufacturers to run machines at higher speeds without sacrificing product quality.

By increasing throughput, companies can fulfill orders faster, optimize machine utilization, and reduce energy consumption per unit produced. This efficiency gain translates directly into improved profitability and competitive advantage.

Extended Tool Life and Reduced Downtime

Investing in precision tooling often means using superior materials and advanced manufacturing techniques, such as CNC machining and surface treatments. These tools are more resistant to wear, corrosion, and thermal stresses common in extrusion environments.

Longer tool life reduces the frequency of costly downtime for maintenance and tool replacement. Consistent tooling performance also helps maintain stable production parameters, avoiding disruptions that can lead to defective products and wasted resources.

Enhanced Product Quality and Customization

Precision tooling enables manufacturers to achieve complex and detailed product designs with tight tolerances. This capability is especially important for industries requiring specialized plastic profiles, such as medical devices, electronics, or automotive components.

With precision tools, companies can customize extrusions to exact specifications while maintaining efficient production rates. This flexibility supports innovation and allows businesses to meet diverse customer needs without compromising on quality or speed.

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US and has almost 60 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog