The Versatility of Custom Plastic Extrusions in Consumer Goods

Custom plastic extrusions continue to enhance consumer goods by offering design innovation, durability, and cost efficiency. Their adaptability ensures they remain integral to advancing product development and meeting consumer expectations.

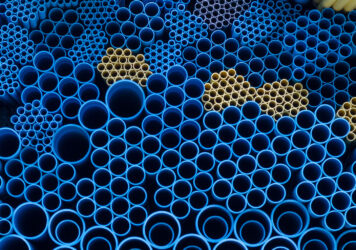

Custom plastic extrusions play a pivotal role in the consumer goods industry, offering exceptional versatility to meet diverse needs. Below is an overview of their significance and applications.

Advantages of Custom Plastic Extrusions

Design Flexibility

- Custom plastic extrusions allow manufacturers to create intricate shapes, profiles, and designs tailored to specific product requirements.

- They can incorporate unique features such as grooves, hinges, or complex geometries that enhance product functionality.

Material Versatility

- A wide variety of plastics, including PVC, polycarbonate, and acrylic, can be used depending on the desired durability, transparency, or flexibility.

- Additives can improve UV resistance, color retention, or fire retardancy, broadening the scope of applications.

Cost Efficiency

- Extrusions reduce material waste by precisely producing required profiles.

- Scalable production makes it economical for both small-batch and large-scale manufacturing.

Applications in Consumer Goods

Household Products

- Profiles for window seals, shower enclosures, or kitchen appliance trims.

- Components such as drawer slides or shelving supports.

Electronics and Gadgets

- Protective casings, cable management solutions, or display bezels.

- Lightweight, durable extrusions for wearable devices or accessories.

Automotive Accessories

- Custom trims, weatherstripping, or dashboard components.

- Extruded parts for cup holders, organizers, or air vent supports.

Retail and Packaging

- Display frames, product holders, or shelf edging.

- Plastic extrusions are used in customized packaging solutions, including protective caps or covers.

Sports and Leisure Equipment

- Profiles for gear storage racks, water bottles, or fitness equipment.

- Lightweight and impact-resistant components for outdoor products like backpacks or tents.

Sustainability and Innovation

Eco-Friendly Options

- Recyclable plastics or bio-based materials can reduce environmental impact.

- Manufacturers increasingly opt for sustainable practices in extrusion processes.

Advanced Technologies

- Co-extrusion enables combining multiple materials in one profile, enhancing product properties.

- Integration of smart materials for IoT-enabled consumer goods.

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US, with over 50 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog