Plastic Customization Services

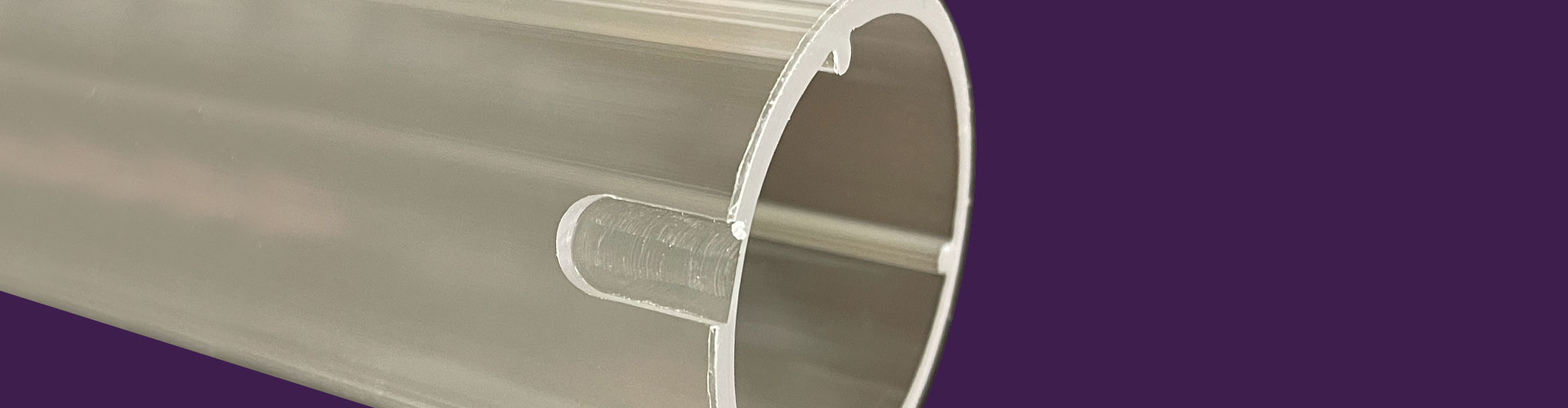

Inplex uses custom plastic co-extrusion and tri-extrusion processes to manufacture plastic tubing and plastic profiles according to your exact specifications. The plastic co-extrusion process involves the simultaneous extrusion of two layers of material through the operation of multiple thermoplastic melt streams and tri-extrusion uses the same method handling three different materials in the same plastic extrusion process.

A range of materials of varying rigidities can safely go through either the co-extrusion or tri-extrusion processes, which work to melt and push different plastics through a single die and then extrudes the materials into any shape you desire. From flexible to rigid, transparent to opaque, and any color you desire– our in-house tooling will co-extrude your version of perfection.

Our values ensure that we understand your needs completely, customize materials specifically, and manufacture your products exactly.

Plastic Tri-Extrusion

Tri-extrusion offers all of the same features and benefits of co-extrusion while handling three different materials in the same plastic extrusion process.

Dual Durometer and Color

Dual Durometer uses materials with different hardness – flexible and rigid, such as a hinged profile. Dual Color uses different colors incorporated into one continuous part.

Added Value

Custom Colors & Durometer

- Flexible

- Rigid

- Transparent

- Translucent

- Opaque

- Stock or custom colors

Exact Specifications

- Cut to length

- In-line fabrication

- Secondary operations

- Materials Used